Turquoise or Firouzeh is used in both jewelry and copperware, silver, nickel or bronze and is responsible for their decoration.

Among the precious stones, turquoise is of great importance. Turquoise is one of the stones that is extracted from Neishabour mines and is world famous for its quality. As a criterion for measuring the value and quality of turquoise in the global market of Neishabour turquoise.

Turquoise stone is available in green and blue colors and each has different qualities. In addition to Neishabour, there are turquoise mines in Kerman and Damghan. The structure of turquoise is such that it has a high sensitivity and is considered as one of the living stones in the world. This means that if the turquoise storage area or chemicals are not placed next to them, the stone will change color. If this damage is acute, the so-called turquoise workers, the stone is dead and can not be restored. In the first stages of changing the color of turquoise stone, turquoise can be revived, which must also be done by masters.

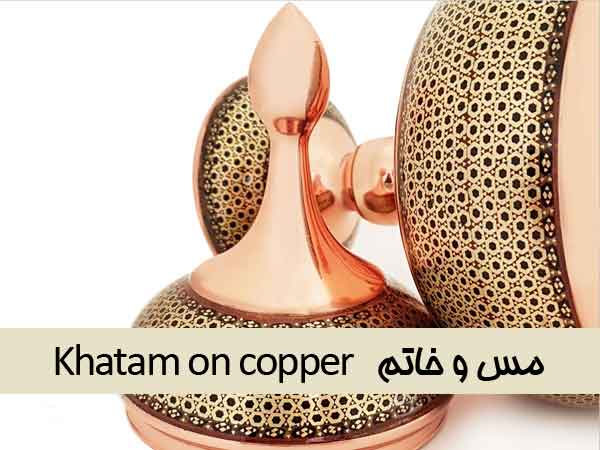

Turquoise or Firouzeh-khubi is one of the most popular Iranian arts that is 60 or 70 years old. In Isfahan, more than other cities, the art of turquoise is covered. If you visit Isfahan and want to take a souvenir; After delicious turmeric, turquoise dishes are one of the best options. Because one of the most important handicrafts of Isfahan is turquoise.

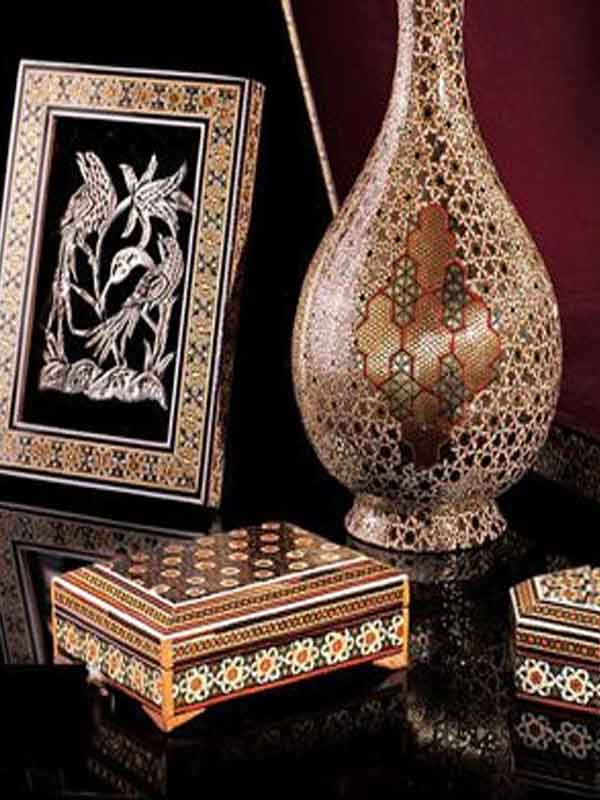

Raw utensils used in turquoise handicrafts are usually made of copper or brass and have good durability. The variety of turquoise products is huge. Turquoise dishes include: vases, lavender, candlesticks, sugar, chocolate eating, pastry eating, fruit eating, eating nuts, sangab, syrup eating, tang, mirror, kashkol, etc. The color of turquoise dishes is generally blue and green. Even in the design of the same objects, the designs and shapes are different.

and accuracy of the parts used. The cleaner and more regular the turquoise work, the higher the price. Turquoise dishes are polished and shiny. The whole part of the dish is level and there are no unfamiliar bumps or depressions in it.

One of the signs of a valuable turquoise is that the black lacquer used in it is less obvious and the turquoise stones used in it have a cleaner arrangement. Of course, the sanding of the dish is done correctly and the surface on the turquoise parts is not different from the surface of the dish.

Turquoise is a beautiful and delicate art that has a dazzling decorative aspect. Utensils, jewelry and objects in which turquoise is used always have a special effect, have material and artistic value and remain in the memories. These dishes are very stylish for use in work and home environments or home décor.

In turquoise pots, in addition to having turquoise on copper or brass, they have also designed a pattern. These dishes have a clear and polished surface. Because these dishes have a polyester coating that, in addition to covering the copper container and preventing it from reacting with oxygen and blackening it; It makes it strong and durable.

So when choosing a dish, be careful that there are no stains in it. Look at it carefully or touch it well to make sure the dish is level.

The more payments in the containers, the more elegant and expensive the container becomes. For art lovers and hardliners, these dishes can relieve your worries about choosing the right gift for such people.

Turquoise containers such as vases or turquoise pots are generally the taller they are worked on and therefore more expensive.

The production of turquoise dishes includes two general steps, which we will examine in the following.

The goldsmith makes the preparation and preparation of the object intended for decoration with turquoise using one of the metals. This is done by a goldsmith using a hand, a press, or both.

Once the object, which is a piece of jewelry or a dish, is ready, the part, which is decorated with turquoise, is made of a thin metal string (the same material used to make the object) called a “candle”. It can be placed around the container and injected into it.

This section creates a wall around the desired shape two or three millimeters above the surface of the container. This is usually done by Turquoise. If the part prepared for the turquoise decoration is too empty, the same metal strands are placed inside it for smaller patterns of decoration (such as flowers, shrubs, etc.) and boiled again. This makes the work more beautiful and makes the worn surface of the turquoise stronger.

First of all, turquoise is bought from its chips from turquoise design workshops or mines in Mashhad, Neishabour or Damghan. Because these turquoises are usually associated with ordinary chips and rocks, they are separated and cleaned for the first time. Then, turquoise chips are graded by size, so they are suitable for making any turquoise object. In the next step, the body is heated (about 30 degrees Celsius) and when heated, the varnish is placed on the parts on which turquoise should be placed to cover the desired surface.

While the lacquer is still soft and sticky on the surface of the body, some of the pre-prepared turquoise chips are on the work surface. The chips must be positioned so that the space between them is lost as much as possible. To fill any gaps between the turquoise chips, a temperature of about 40 degrees Celsius is applied and more lacquer powder is sprayed on the chips to soften the lacquer. Then they remove all the spaces by adding turquoise chips on the surface. This is usually done by pressing the turquoise chips on the surface manually. After the effect is completely dry, the transparent parts are covered.

After that step, the parts that are covered with varnish and turquoise are polished by welding, so the extra varnish and a few pieces of chips are flattened. It is at this point that the turquoise chip and the black and white (or dark brown) lacquer are visible in the spaces between them. After completing this step, if there are still gaps in some of the work areas, the body is reheated and the empty parts are rebuilt with small turquoise chips and varnish.

The effect surface is then re-polished. It is sometimes repaired with a type of turquoise putty made from colored flowers and oils. The final stage is turquoise payment, which is done in two stages. The first step involves burning metal parts, which is done in a gold or machining workshop, in which the opaque layer placed on the metal parts at the time of the turquoise injection is removed, then the container is polished and the metal is polished. The second step involves burning the turquoise product.

After polishing the metal parts, the work is returned to the sheet turquoise workshop where the surface of the work is polished with olive or sesame oil to make it shiny.